OUR SERVICES

Whether you're an established firm looking to outsource—or in the early stages of design—we can help you get where you need to be, fast.

We specialize in custom design and digital fabrication using sheet goods. Located conveniently in downtown Victoria BC, we serve clients across Vancouver Island and beyond.

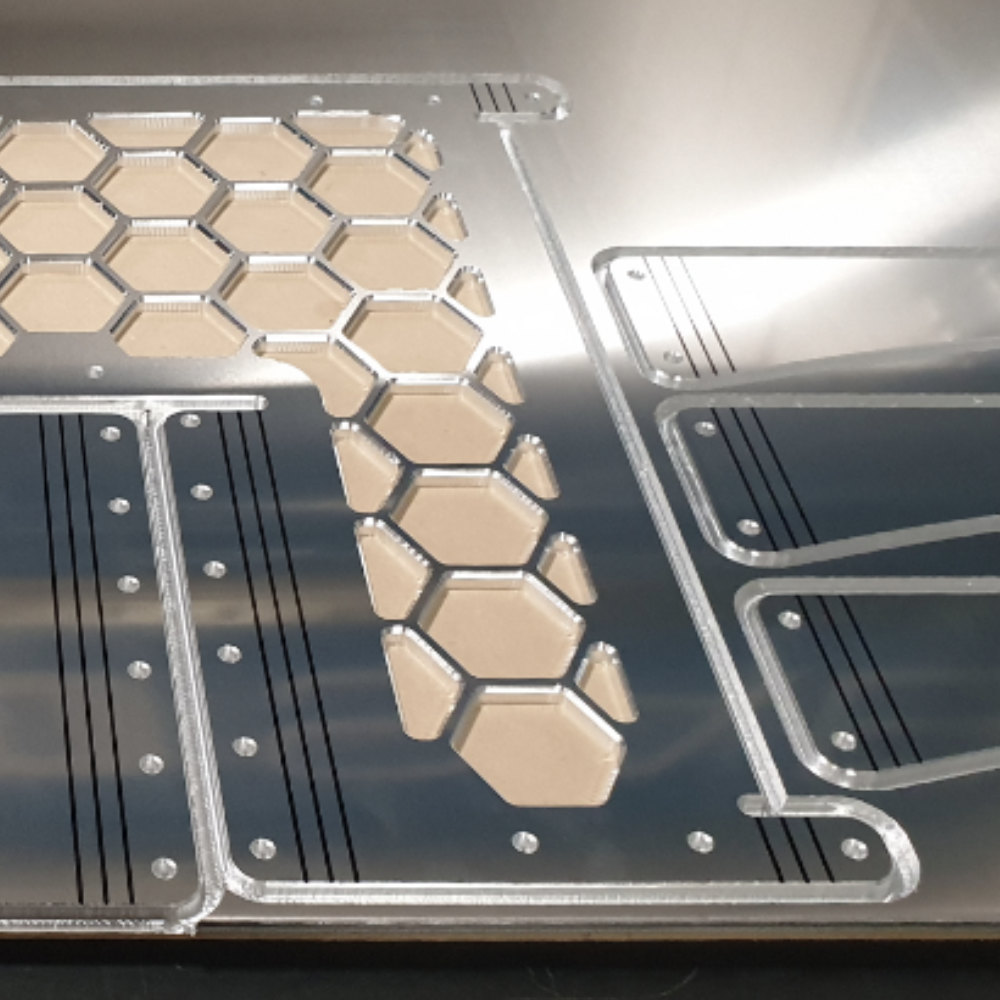

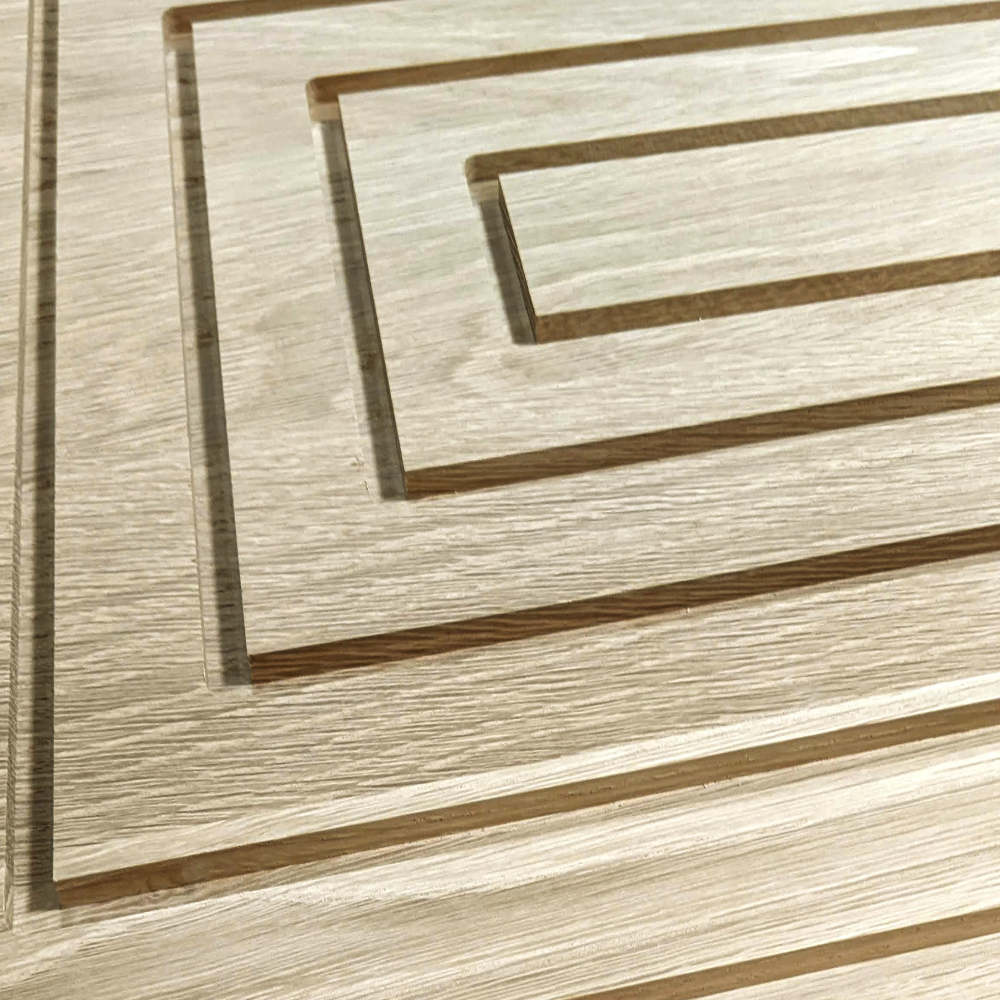

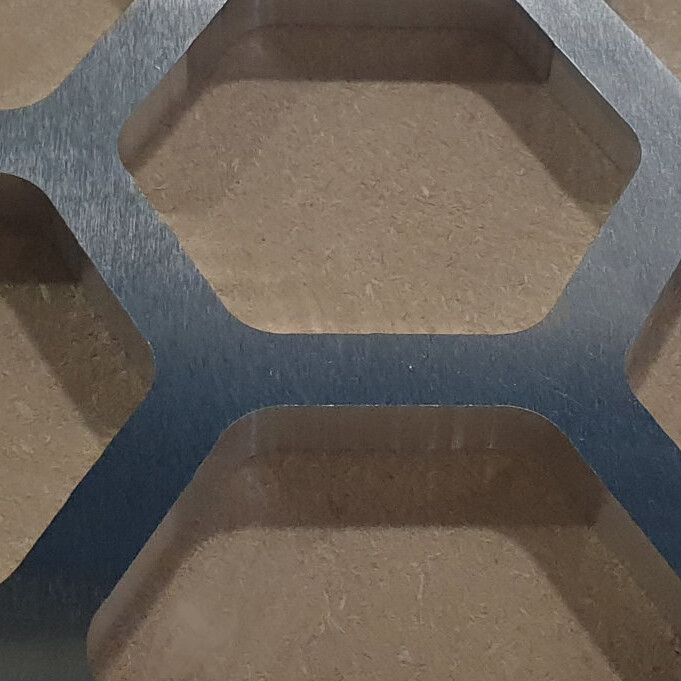

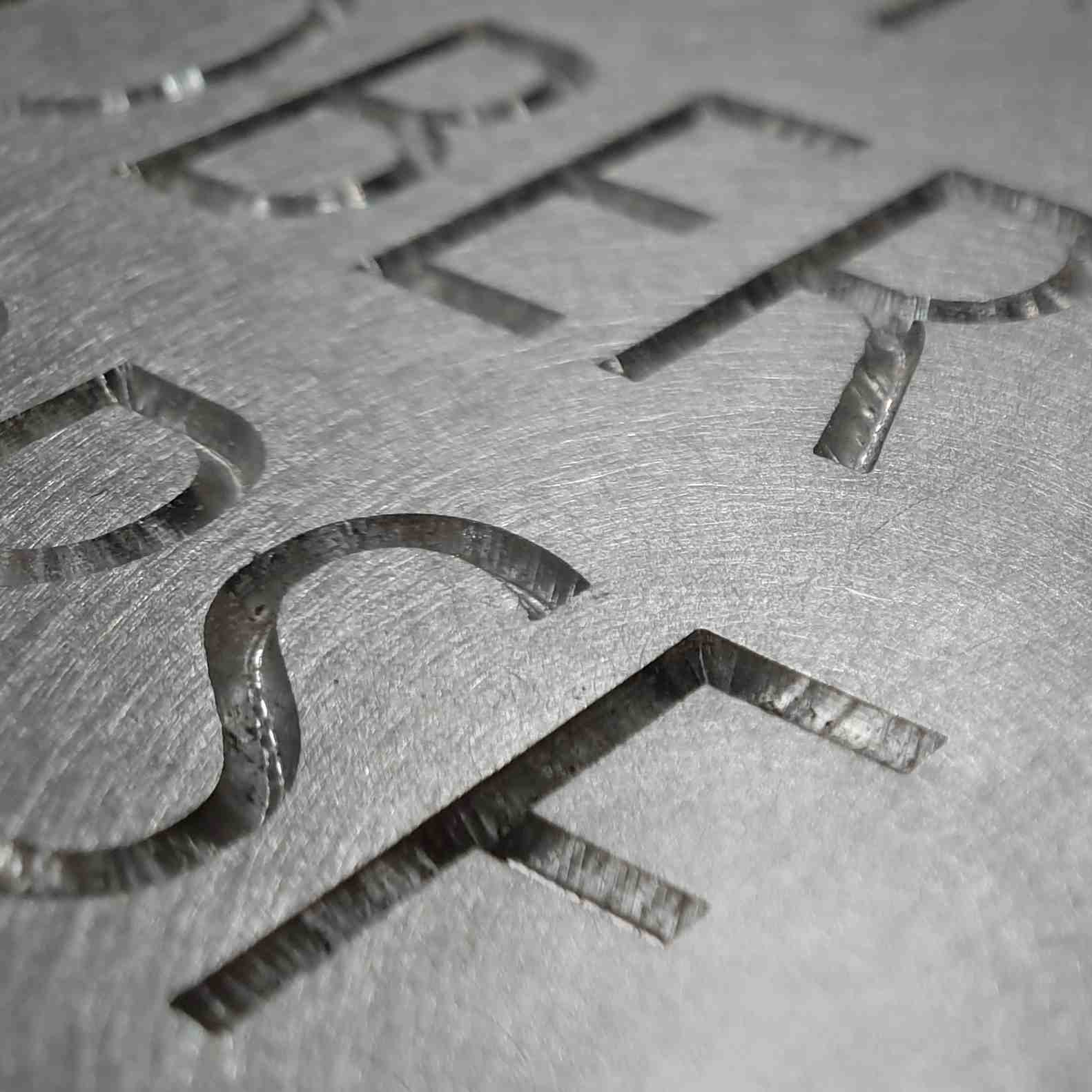

Our CNC machinery mills wood, melamine, MDF, aluminum, brass, composites such as fibreglass and carbon fibre, and a wide range of plastics such as acrylic, foam, polycarbonate, plexiglass and solid surface materials. What is CNC machining?

Click on each of our services below to learn more.

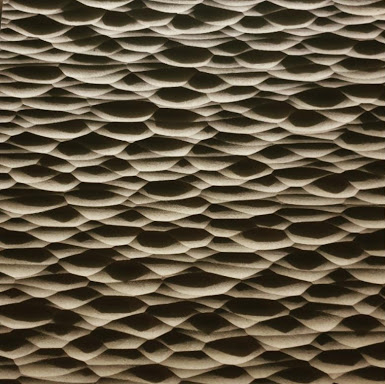

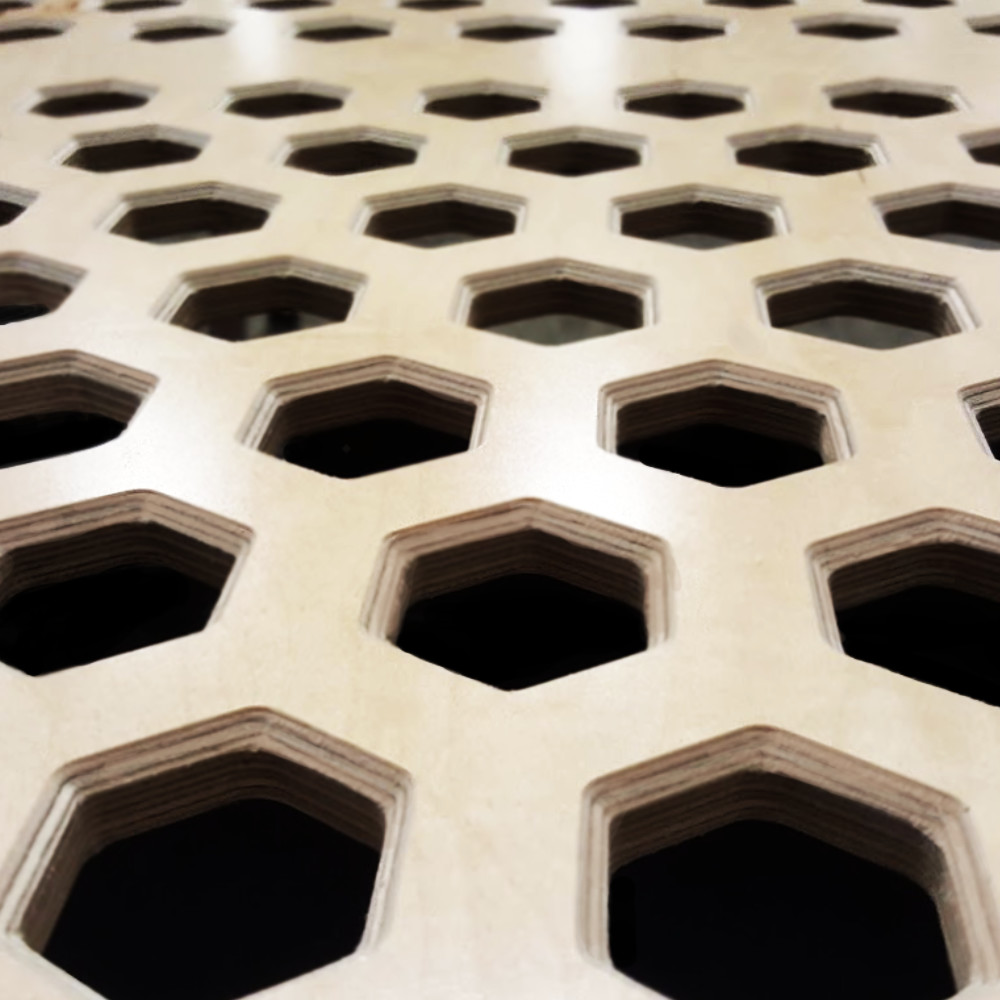

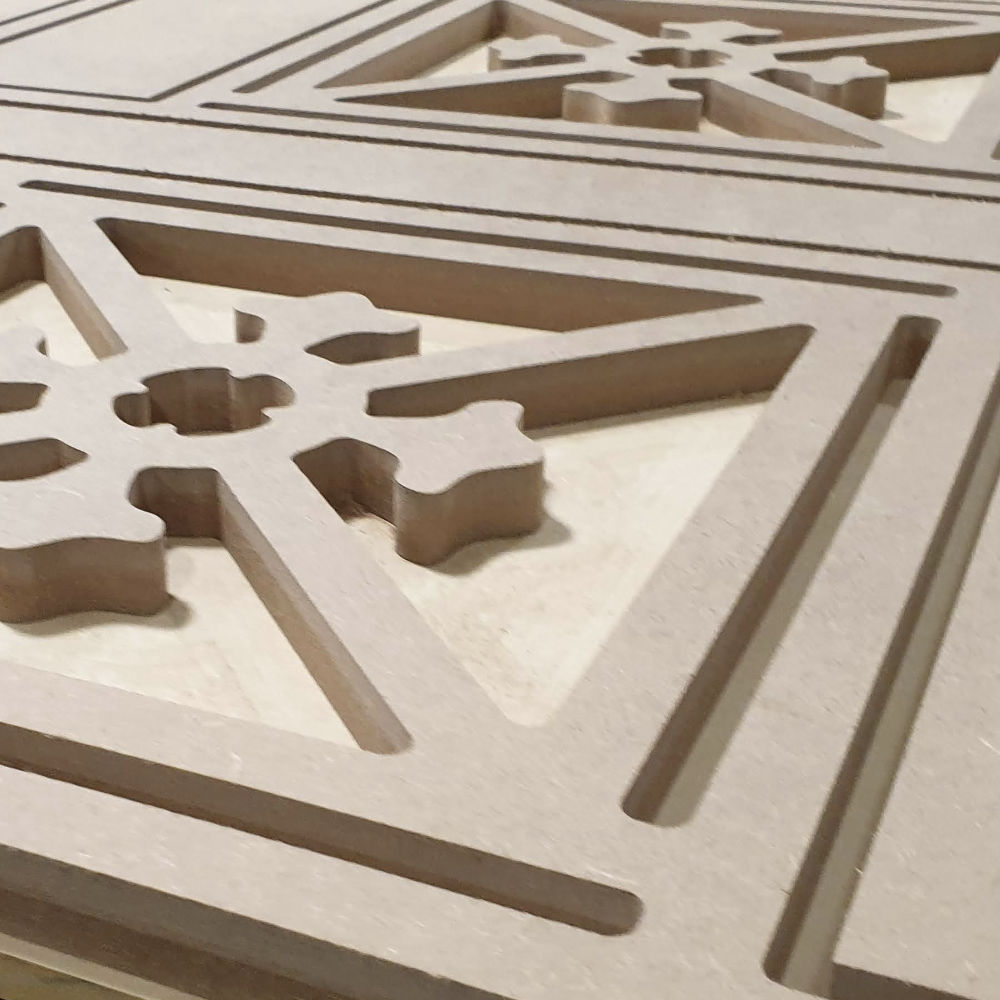

We provide fast 2D and 3D CNC machining of a wide variety of materials. Our maximum cutting area is an extra large work envelope of 5’x8’x1′, easily fitting a 4×8 sheet of plywood (length can be doubled to 200” by indexing and rotating parts). Our ShopSabre Pro 408 CNC is capable of three and four axis machining. We can supply your materials and provide post-processing in house, or you can simply bring us your materials to cut, and then finish them yourself.

We provide custom millwork for the interior design, cabinetry, boating, and recreational vehicle industries to name a few. Residential, commercial and heritage features can be recreated for interior and exterior applications.

We love solving problems! Bring us your complex design challenge for a space or a product, and we’ll work closely with you to find a solution. With our expertise in millwork and custom interiors as well as Design for Manufacturing and Assembly, we’ll ensure your design is optimized for ease of production with the best result at a lower cost.

Got a product idea to test? Our in-house parametric modelling paired with a full CNC machine shop and 3D printers will move you quickly to a proof of concept and on to production, all under one roof. We can cut a foam mould for shaping your material and provide expert advice on material selection.

Whether your goal is to scale up, reduce costs by outsourcing manufacturing, or bring your product to market for the first time, we have the expertise to help you evaluate options and pitfalls using a systematic and thoughtful process. Learn more

One of the highest value offerings of CNC machine technology is our ability to produce the same parts again and again with razor sharp precision. Whether you’re looking to increase the efficiency of your cabinetry operation or order a run of specialty metal parts, our in-house processes shorten cutting times, reduce waste and lower costs for you. Our machinery is capable of such operations as:

- Addition of numbers, logos or assembly information to parts using V-carving, diamond drag etching, laser engraving or pen plotting

- Through-cuts, pockets, chamfers, roundovers, slotting, textures, flattening, 3D surfaces, mitered edges, holes, countersinks, counterbores and more

- Jointery for ease of assembly and extra strength, such as dadoes, rabbets or box joints

- Cutting and assembly of single or multi-part molds, bucks, templates, jigs and assembly fixturing to increase producing speed while ensuring process reliability

Learn more about our product manufacturing.

We’re experts in digital fabrication. We can turn your napkin drawings into fully rendered digital CAD models that are ready to support real world production. Designing your parts digitally first with our software allows for quicker iteration and saves money and time. Our primary software is Autodesk Fusion360 but we can also use a variety of other CAD packages.

We have Fused Deposition Modelling (FDM) 3D printers in house, with access to almost every other type of 3D printing available for manufacturing parts and prototyping. We’ve got you covered when this exciting new technology is identified as the right fit for your business goals. Our 3D printer boasts multi colour and multi material capability as well as ultra FDM high quality printing with 7 μm lidar resolution. Learn more about how we can manufacture your products.

Our 5′ x 8′ work area for laser engraving is one of the largest on southern Vancouver Island. Engraving is available for signage, custom products and more.

There’s no shortage of large wood slabs in our neck of the woods. These expensive and precious pieces always twist, cup and warp in the drying process. Save yourself hours—or even days—of work and let us handle the flattening. Maximum slab size is 5′ x 16.5′ and 1′ thick. We can also turn your flattened slab into a sign, countertop or custom furniture.

Our shop is fully loaded with everything we need to bring your dreams into reality. Come down to one of our open houses and say hello! Learn more about our workshop located in the historic Powerhouse.

Whether you’re brand new to the field or a seasoned veteran requiring a bit of support with your CNC machine, we’re happy to help. We’re experts in computer-aided design (CAD) and computer-aided machining (CAM) too. We do virtual training and on-site visits across Vancouver Island and the Lower Mainland. Contact us today to discuss your needs.

5-STAR RATING ON GOOGLE

Marc understands the skill of translating words into drawings and then to finished product. The project I worked on with him was very complicated but Marc always kept his communication tight and double checked before fabricating. I highly endorse his skills as a CNC company.

- Rogier van Tilburg, Dutch Carpenter and Co.

★★★★★

Marc does fantastic work and he's a super nice guy to boot. We gave him a questionable file for a complicated project, and he put in the time and effort to get us an end product that was exactly what we were looking for. I highly recommend.

- Steve Webb, Metropol

★★★★★

I came to Marc and his team a few months ago to work on a prototype I needed to have made for my business. The design and prototype Toolpath Design created has far exceeded my expectations of anything I could have envisioned. I would highly recommend Marc and his team for any of your ideas or creative work you need done. Thank you guys again and i look forward to continuing to work with you into the future!

- Adam Kaufmann, DubTub

★★★★★

I gave Marc an amateurish Sketchup file and a piece of MDF and he quickly produced—at very reasonable cost—exactly what I needed, in the blink of an eye. Highly recommended!

- Carey Swoveland

★★★★★

Toolpath was instrumental in helping me produce a successful working prototype of my product. I started with a simple sketch, Marc translated it into a beautifully improved design and came up with an efficient production process. Now the orders are coming in.

- Justin Radford, WESK Workspaces

★★★★★

Not only is Marc extremely knowledgeable in CAD/CAM and materials, he is so kind, easy to work with, and a great communicator. Couldn't recommend him enough!

- McCauley Wanner, ALLELES Design Studio Ltd.

★★★★★

Marc made our office sign and a few artistic wood carving maps for my organization and every time he exceeded my expectations. I gave him a crumby drawing and a rough idea and what came out was incredible. Thanks Toolpath!

- Keith Holmes, Hakai Institute

★★★★★

Friendly and creative! Excellent workmanship - love working with Toolpath!

- Jamie Clarke, Avalon Mechanical

★★★★★

CNC Master Marc's skill, talent and services were awesome. I need a few specific wooden parts done for my inlay project and Marc made it happen! He was amazing to work with. I look forward to our next creation, thank you.

- Hermesh Austin

★★★★★